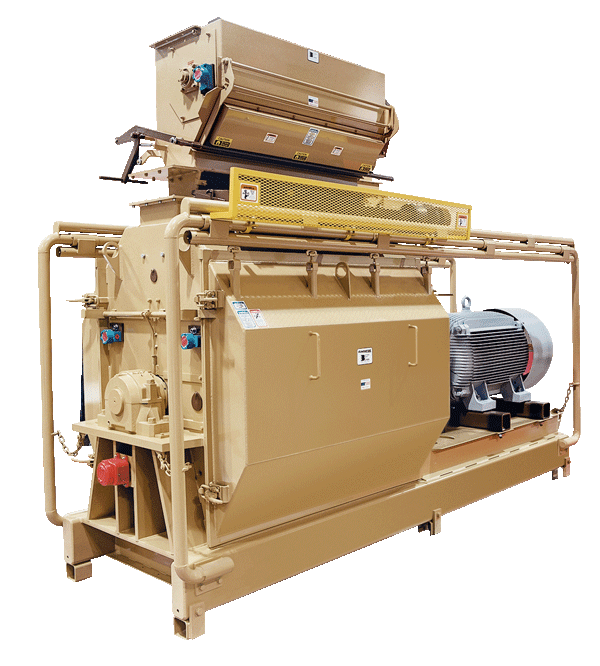

Eliminator Hammermill

Increase your productivity and profits with a Bliss Eliminator Hammermill. Such features as internal wear plates, recessed reversible rotor, vortex cutter bar, one-piece plate housing, 3/8″ plate doors, octagonal shaped housing, double drilled rotors, and one-piece screen carriage maximize your grinding efficiency. Every Hammermill is individually sized based on research and decades of experience to fit your unique application and needs.

Each Eliminator is backed with our “post-sales service program” providing continual support via our fully equipped and experienced service team and a complete line of OEM parts. The Eliminator Hammermills are used in an extensive variety of applications including: wood, paper, cereal grains, by-products, oil seeds, food products, pet, and aquatic feeds.

Quality Features

- Doors – Heavy-duty 3/8″ plate doors hinge left, right, or slide open so they can be completely removed for greater accessibility and can fit any space restraints – this is not an option, but a standard feature on every Bliss Hammermill.

-

Internal Wear Plates – The Eliminator is designed to do all the grinding against replaceable wear plates. Never against the mill housing.

-

Screen Carriage – The Eliminator’s one-piece screen carriage is manufactured of round rod and flat mild steel.

-

Screen Carriage Lock – The extra heavy-duty carriage locks are one-piece in construction.

-

Screens – Bliss utilizes all staggered perforated screens with no special mounting angles, flanges, or bands.